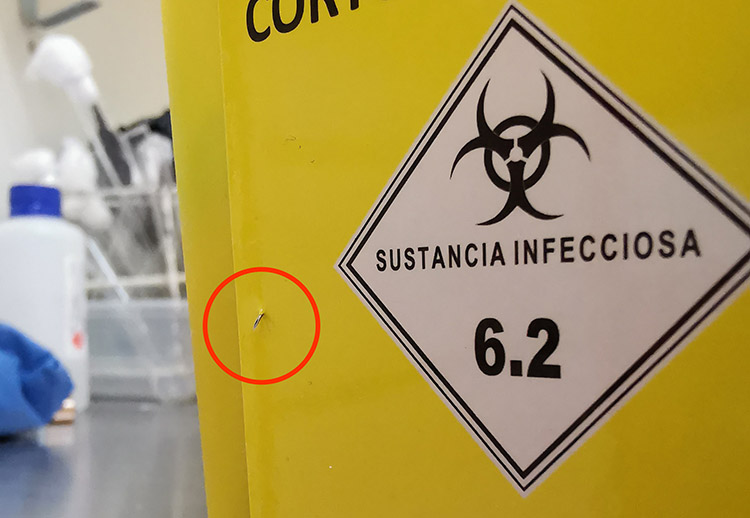

How to deal broken sharp container if the sharps container body pierced during use

There may be a very small probability that the sharp container box is pierced by an infected medical sharp. Generally, it is caused by the following two reasons:

1. The sharps container box is over full. Forcibly inserting sharp objects such as syringes and needles inside will cause the sharp objects inside to squeeze, and the needles will pierce the inner wall of the sharps box and expose;

2. The sharps container box is defective. Part of the barrel body is too thin, and the needle is just perpendicular to the inner wall. After being squeezed by an external force, the needle pierces the inner wall and is exposed.

What should to do when the sharps container box is pierced or damaged? You should stop discarding medical waste sharps in the sharps box immediately, even ordinary medical waste. Put on nitrile medical gloves and set the lid to permanent Close the state, then put the entire sharps box in a trash bag, and throw it into a special trash can for storing used sharps boxes. After disinfecting your hands, put on new ordinary medical gloves, take out a brand new sharps box and continue your work.

So how to avoid the above two situations from happening?

Do not overload and fill the sharps container. Strictly follow the instructions on the label. When the medical sharps waste inside reaches the loading warning line, you should stop continuing to fill the medical waste. If you accidentally stuff a long needle into the small sharps box. When blocking, do not forcibly stuff it inside, take it out and stuff it into a large-size sharps container box. After the sharps box is full, close the lid permanently, and put the sharps box in a professional recycling trash bin.

Do not use sharp boxes that are of unknown origin or are too cheap. Try to use products produced by regular manufacturers. Production processes and product certifications that meet international standards are preferred.

Dailymag has a strict process in sharps contianer production, quality control and inspection. The injection molding machine has an intelligent alarm system. If there are defects in the plastic parts, such as missing corners, cracks, and uneven thickness, an alarm will be issued. The operator will check and pick out the defective products. The first pass of the injection molded plastic parts can ensure the production quality. Before entering the packaging process, each barrel body and lid accessories will undergo a full manual appearance inspection, and the accessories that are found to be defective or incorrect in color will be picked out. Before the packaging is completed, a dedicated quality inspector will conduct a random inspection on the quality of each batch of sharps boxes. In addition to the regular appearance inspection and label inspection, the product will also be tested for puncture resistance, 1 meter drop, etc., to ensure Every sharp container delivered to the user is of qualified quality. Although the sharp tool box is only a one-time use product, Dailymag is always responsible for its customers.